TRANSMISSION SYSTEM,SHAFT AND UNIVERSAL JOINT

TRANSMISSION SYSTEM

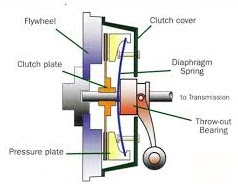

Clutch Assembly

A clutch is a mechanical device which engages and disengages power transmission especially from driving shaft to driven shaft. In the simplest application,clutches connect and disconnect two rotating shafts (drive shafts or line shafts).

Types of clutch

Different types of clutches are as follows:

1. Friction Clutch

Single plate clutch

Multiplate clutch

• Wet

• Dry

Cone clutch

• External

• Internal

2. Centrifugal Clutch

3. Semi-centrifugal Clutch

4. Conical Spring Clutch

4.Diaphragm Clutch

- Tapered finger type

- Crown spring type.

5. Positive Clutch – Dog and spline Clutch

6. Hydraulic Clutch

7. Electro-magnetic Clutch

8. Vacuum Clutch

9. Over running Clutch or free-wheel unit.

Principle of Friction Clutches

The Principle of a friction clutch may be explained by means of above figure.

Let shaft A and disc C be revolving at some speed, say N r.p.m. Shaft B and the disc D keyed to it are stationary, initially when the clutch is not engaged. Now apply some axial force W to the disc D, so that, it comes in contact with disc C. As soon as the contact is made the force of friction between C and D will come into play and consequently the disc D will also start revolving. The Speed of D depends upon friction force present, which in turn, is proportional to the force W

applied. If W is increased gradually, the speed of D will be increased correspondingly, till the stage comes when, the speed of D becomes equal to the speed of C. Then, the clutch is said to be fully engaged.

Let W = Axial load applied

T = Torque transmitted

R = Effective mean radius of friction surface.

Then, T = μWR

Thus, we see that the torque transmitted by a friction clutch depends upon 3 factors i.e., μ W and

R. This means that increasing any or all of the above factors would increase the amount of

torque which a clutch can transmit. However, there are upper limits in each of these cases.

Gear Box (Transmission) Assembly

Need of a Gear Box

An auto-vehicle has to run on roads of various qualities and types, and at varying speeds. It alsoencounters with vivid nature of tyre-road adhesion, on level and sloped roads. Having differentbody profiles, various driving needs such as idling and quick acceleration etc., and widelyvarying driving habits of drivers, the vehicles have to overcome several resistances also.Moreover, they also meet the variations in tractive effort at various speeds. Various resistancesencountered by the auto-vehicle during its operation are1. Rolling resistance which mainly depends upon

- Material of the road surface : cemented, asphalted etc.

- Quality of the road surface : smooth or rough, dry or wet etc.

- Material and design of tyres tread

- Inflation (pressure) in the tyre : over-inflated, under-inflated, or correctly inflated

2. Gradient resistance which mainly depends upon

- Slope of the road : level, sleepy, down-a-hill, up-the-hill etc.

- Mass of the vehicle : light, medium or heavy

3. Air resistance which mainly depends upon

- Speed of the vehicle : slow, medium or fast

- Speed and direction of the wind : in-favour, against the vehicle’s motion or crosswinds

- Body profile of the vehicle : streamlined, bluff body or otherwise

4. Resistance due to driving requirements which mainly depends upon

- Need of idling, or constant speed

- Acceleration and its rate

- Frictional resistance.

Sum of all these resistances is known as Total Resistance.

Types of Transmission (Gearbox)

Several kinds of transmissions are employed on auto-vehicles. These can be classified as follows:1. Manual Transmission

- The manual transmission i.e., the selective type gearboxes are the conventional means.

- They are widely used in cars, bases and trucks. It is also known as standard or

- conventional type Gear box.

- Sliding mesh gear box

- Constant mesh gearbox

- Synchromesh gearbox without overdrive

- Synchromesh gearbox with overdrive.

2. Semi-automatic transmission

- Semi-automatic transmission incorporates an intermediate arrangement which is

- combination of manual and automatic systems.

- Electric controlled with a fluid drive.

- Electric controlled with overdrive.

- Fluid-torque drive.

Automatic transmission is used mainly on luxury cars, or heavy vehicles which require frequent change of gears in the city and crowded highway driving. In automatic transmission, the different ratios between the engine crankshaft and the wheels are achieved by automatic means. The driver does not need to shift gears, such transmission

- make use of a fluid coupling or torque converter, as well as mechanical, hydraulic or electrical controls.

- Hydromatic drive

- Torque-converter drive

Principle of Gearing

A simple Gearing principle is shown below where two gear are engaged with each other. Gear A is called Driving Gear or Driver and Gear B is called Driven Gear.Suppose,NA = Speed of Gear A T = Number of teeth on Gear A ANB = Speed of Gear B T = Number of teeth on Gear B BTherefore, the speed ratio of Gear A and Gear B

With the following example, the principle of gearing will be very clear to you.

Comments

Post a Comment